Special Services

Experience DaVinci Aerospace’s specialized services, where precision meets innovation. From Aluminum Anodizing and Zinc Plating to Powder-Coating, Magnetic Particle Inspection, and advanced Heat Treatments, we redefine industry standards.

Plating

- Aluminum Anodizing Type 2 & 3

- Passivation Stainless Steel

- Zinc Plating

Painting

- Powder Coating

- Epoxy Coating

- Epoxy Priming

Non-Destructive Testing

- Magnetic Particle

- Dye Penetrant

Heat Treatment

- Non-Ferrous Metal Processing (Aluminum, Copper Alloys)

- Ferrous Metal Processing (Steel)

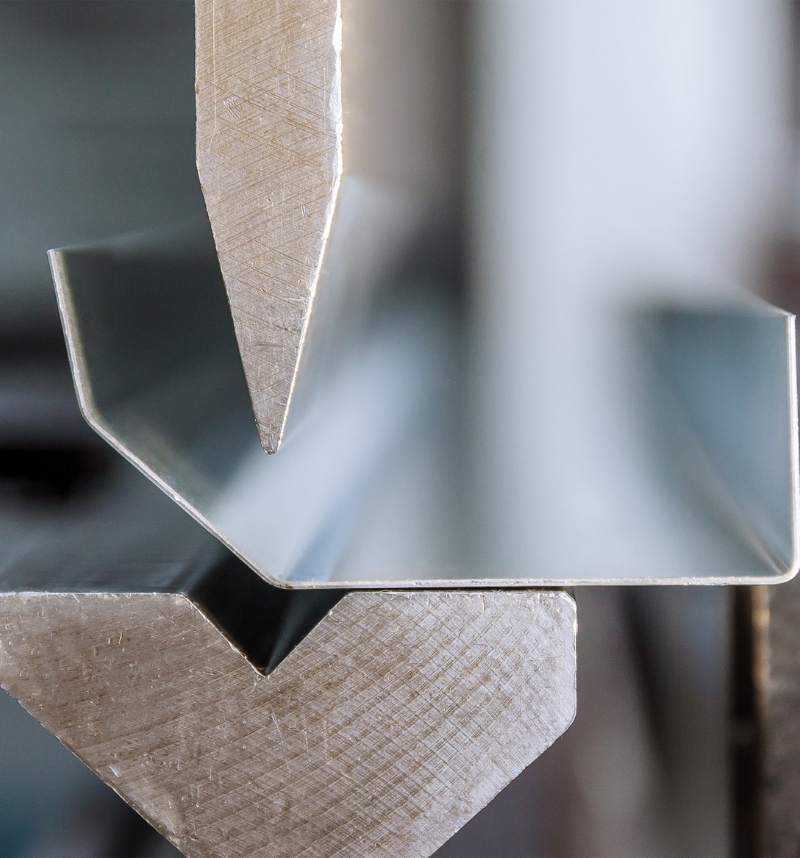

Plating Services

At DaVinci Aerospace, we understand the vital role that quality plating services play in the functionality and durability of aerospace and defense components. Our specialized plating services are designed to meet the unique needs of these demanding industries.

Aluminum Anodizing Type 2 & 3

Aluminum is a metal of choice in aerospace for its balance of strength and lightweight properties. To enhance its natural corrosion resistance, we offer both Type 2 (Sulfuric) and Type 3 (Hardcoat) Aluminum Anodizing. This electrochemical process creates a hard, protective oxide layer on the aluminum surface, ensuring your parts can withstand even the toughest conditions.

Passivation – Stainless Steel

Our stainless steel passivation service helps to maximize the inherent corrosion resistance of this versatile alloy. Through a carefully controlled chemical process, we remove surface contaminants that could potentially compromise the metal’s passive layer. The result is a clean, highly resistant surface ready to meet the demands of the aerospace and defense industries.

Zinc Plating

For components that require an added layer of protective coating, our zinc plating service provides an excellent solution. The zinc coating acts as a sacrificial layer, protecting the base metal from rust and corrosion. Ideal for steel parts, zinc plating is a cost-effective way to enhance longevity and performance.

Choose DaVinci Aerospace for your plating needs, where we blend cutting-edge technology, extensive expertise, and stringent quality control to provide you with the best possible results.

Painting Services

At DaVinci Aerospace, we offer superior painting services that add not only aesthetic appeal but also durability and functionality to your components. Our painting services are carefully designed to meet the rigorous standards of the aerospace and defense industries.

Powder Coating

Our advanced powder coating service enhances the corrosion and wear resistance of your parts while providing a sleek, uniform finish. By applying a free-flowing, dry powder and curing it under heat, we create a hard, durable coating. This environmentally friendly process results in a high-quality, lasting finish that can stand up to harsh operating conditions.

Epoxy Coating & Priming

For parts needing extra protection against corrosion and chemical exposure, we offer epoxy coating and priming. This two-component system creates a tough, resistant layer on your components, providing exceptional durability and resilience. Epoxy coating is ideal for environments where excellent chemical and moisture resistance is required.

At DaVinci Aerospace, we integrate state-of-the-art technology, industry expertise, and a rigorous quality control process to provide outstanding painting services that meet your specific requirements. Trust us to provide solutions that enhance the longevity and performance of your components.

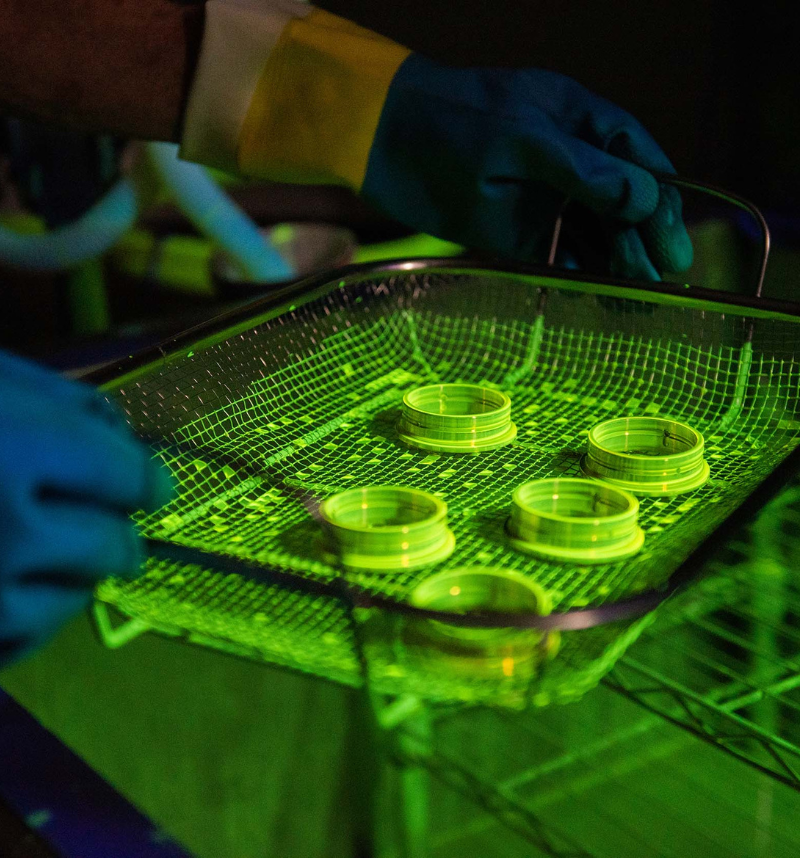

NDT (Non-Destructive Testing)

At DaVinci Aerospace, our commitment to quality and safety extends to our Non-Destructive Testing (NDT) services. We use advanced techniques to inspect and ensure the integrity of components without damaging or altering them, thus providing the highest assurance of performance and reliability.

Magnetic Particle Testing

Our Magnetic Particle Testing service is an effective method for detecting surface and near-surface discontinuities in ferromagnetic materials. By inducing a magnetic field in the part and applying ferrous particles, we are able to identify any flaws that may cause the magnetic field to leak, such as cracks, porosity, or inclusions. This process provides a fast and reliable inspection method, crucial for maintaining the safety and durability of your components.

Dye Penetrant Inspection

Dye Penetrant Inspection is another highly effective testing service we offer, particularly useful for detecting flaws on non-porous material surfaces. In this method, a brightly colored dye is applied to the part’s surface. Any surface-breaking flaws will draw the dye into them, which, when removed and developed, becomes visible under ultraviolet light. This method offers a simple yet precise way to locate surface defects, ensuring your components meet the highest standards of quality and safety.

At DaVinci Aerospace, we are dedicated to delivering superior NDT services. With our meticulous procedures, advanced techniques, and experienced professionals, we ensure the reliability and integrity of your components. Trust us to provide unparalleled insight into the condition and safety of your parts.

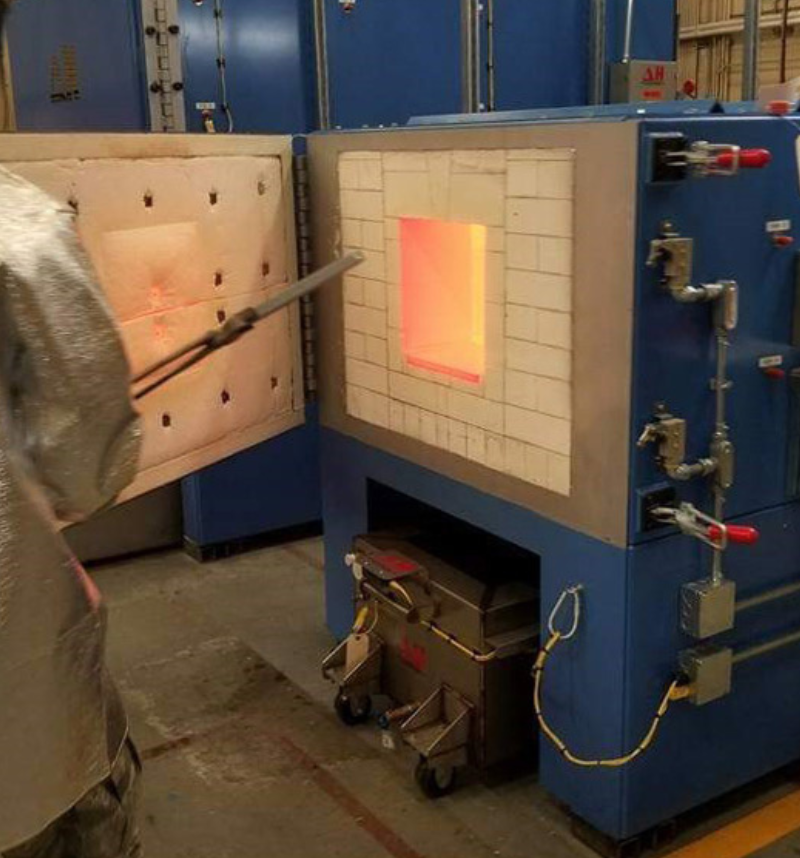

Heat Treatment Services

DaVinci Aerospace is at the forefront of delivering high-quality heat treatment services. Utilizing industry-leading processes, we modify the properties of metals to meet the exacting demands of the aerospace and defense industries.

Non-Ferrous Metal Processing (Aluminum, Copper Alloys)

Our heat treatment services for non-ferrous metals like aluminum and copper alloys are designed to enhance the inherent properties of these metals. The process includes controlled heating and cooling procedures, which optimize the metal’s structural and physical properties, improve machinability, and increase resistance to wear and corrosion.

Ferrous Metal Processing (Steel)

We offer tailored heat treatment services for ferrous metals like steel. By applying a range of processes, including annealing, normalizing, hardening, and tempering, we can significantly improve the metal’s strength, hardness, toughness, and resistance to wear and tear. This ensures that your components perform reliably under the challenging conditions of aerospace and defense operations.

At DaVinci Aerospace, our heat treatment services combine advanced technology, extensive expertise, and strict quality control measures. We are committed to delivering solutions that enhance the durability, performance, and lifespan of your components. Choose us to provide the meticulous care and attention your components deserve.

Contact Us

Visit Us

4500 Green Point Dr,

Greensboro NC 27410

Call Us

Email Us

hello@davinciaero.com